Commercial Concrete Estimating: A Comprehensive Guide

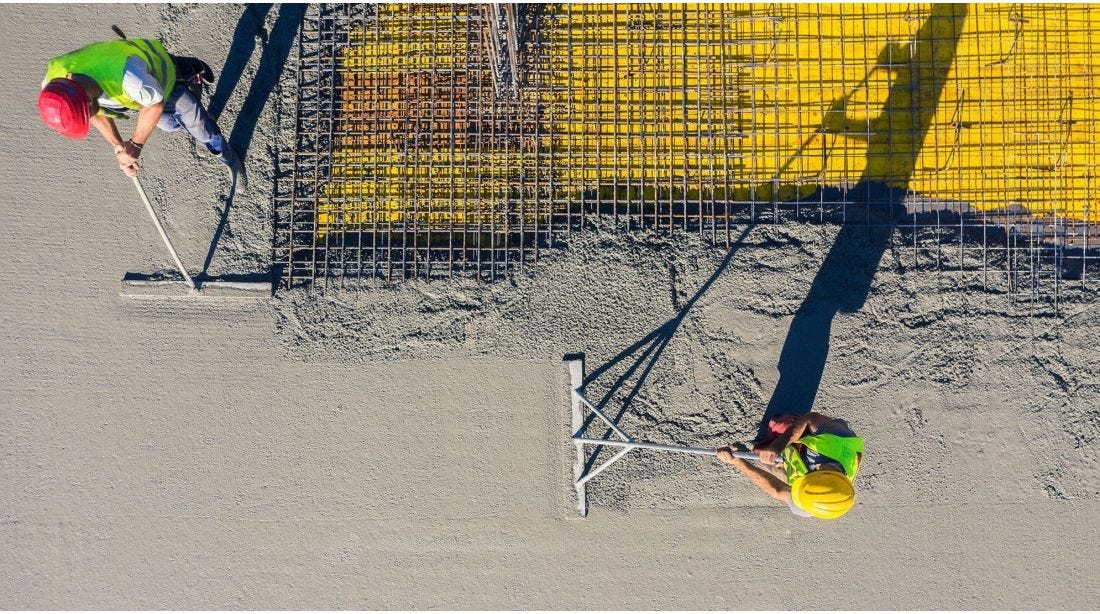

In the world of construction, commercial concrete projects represent a cornerstone of urban development and infrastructure. From high-rise buildings to expansive parking lots, the use of concrete is ubiquitous due to its durability, versatility and cost-effectiveness. However, accurately estimating the cost of commercial concrete work is a complex task that requires a deep understanding of the material, construction processes and the interplay of various cost factors.

In this guide, we will explore the intricacies of commercial concrete cost estimating, outlining the key components and offering insights into the best practices of the trade.

Understanding Commercial Concrete Projects

Before diving into the estimation process, it's crucial to understand the scope and scale of commercial concrete projects. These ventures can vary significantly, ranging from the foundations of large structures to the creation of intricate architectural elements. Each project has its unique specifications, which means estimators must be adept at adapting to different scenarios and requirements.

The Estimation Process

The concrete estimation process for commercial projects involves several steps, each requiring attention to detail and precision:

1. Analyzing Project Plans

The first step in concrete estimating is a thorough analysis of the project plans. Estimators must review the architectural, structural and civil drawings to determine the quantity of concrete needed. Special attention should be paid to the dimensions of the slabs, footings, walls and other structural elements. This analysis lays the groundwork for all subsequent calculations.

2. Quantity Takeoffs

Once the plans have been reviewed, the estimator performs a quantity takeoff, which is the process of determining the exact amount of concrete required for the project. This involves calculating the volume of concrete for each element and considering factors such as waste, spillage and over-excavation. Quantity takeoffs must be precise to avoid costly overruns or shortages.

3. Material Costs

After determining the quantity of concrete, the next step is to calculate the cost of materials. This includes not only the concrete itself but also any reinforcing materials such as rebar or wire mesh. Prices can fluctuate based on market conditions, so it's essential to have up-to-date information on the cost of materials.

4. Labor Costs

Labor is a significant component of concrete work. Estimators need to factor in the cost of skilled labor required to form, pour and finish the concrete. Labor rates can vary by region and are influenced by the complexity of the work and the experience of the workforce.

5. Equipment and Machinery

Concrete work often requires specialized equipment such as mixers, pumps and finishing tools. Estimators must account for the rental or purchase cost of this equipment, as well as any maintenance and operation expenses.

6. Site Conditions and Accessibility

Site conditions can greatly affect the cost of a concrete project. Difficult access, remote locations or challenging terrain can lead to increased labor and equipment costs. Estimators must visit the site to assess these conditions firsthand.

7. Overhead and Profit Margins

Finally, estimators must consider overhead costs such as office expenses, insurance and taxes. Additionally, a profit margin is added to ensure the project is financially viable for the contractor.

Best Practices for Accurate Concrete Estimating

To ensure the accuracy of a commercial concrete estimate, there are several best practices that estimators should follow:

1. Use Reliable Estimating Software

Technological advancements have led to the development of sophisticated estimating software that can streamline the process and improve accuracy. These tools often include features like automatic quantity takeoffs and real-time material pricing.

2. Stay Informed With Market Trends

Material and labor costs can fluctuate due to economic trends, supply chain issues and other market factors. It's important for estimators to stay informed and adjust their calculations accordingly.

3. Include Contingencies

Unforeseen circumstances can impact the cost of a concrete project. Including a contingency in the estimate allows for flexibility to address these unexpected changes without jeopardizing the project’s financial health.

4. Collaborate With the Project Team

Effective communication with the architects, engineers and contractors involved in the project can lead to a more accurate estimate. Collaboration ensures that all technical aspects and potential challenges are considered.

5. Review Historical Data

Estimators should review data from past projects to identify trends and benchmarks that can inform their current estimates. Historical data can provide valuable insights into actual costs and the efficiency of different construction methods.

6. Regularly Update the Estimate

As the project progresses from the bidding phase to construction, costs can change. Regular updates to the estimate are necessary to reflect these changes and to manage the budget effectively.

7. Ensure Compliance With Industry Standards

Following industry standards and regulations not only ensures the safety and durability of the concrete structure but also helps avoid costly fines and delays. Estimators must be aware of the relevant codes and standards for their region.

Commercial concrete estimating is a critical skill that balances precision with practicality. It is a multifaceted process that demands a comprehensive understanding of construction principles, cost analysis and project management. By adhering to the best practices outlined in this guide, estimators can provide accurate, reliable cost projections that are essential for the successful completion of commercial concrete projects.

Looking to leverage an industry-leading construction cost database for your upcoming projects? Start your free trial of RSMeans Data Online today to experience what’s possible.