RSMeans Data: Construction Cost Estimating Software

For a Limited Time, Get 15% off 2024 Cost Books

Simplify Construction Estimating with RSMeans Data

Accurate construction estimates ensure projects are completed within budget and on time, leading to increased profitability and client satisfaction. Our industry-leading construction cost database, RSMeans Data, is available in a variety of formats designed to help you create reliable construction estimates.

Cost Books

Estimating Software

Costworks CDs

2024 Construction Costs Open Forum

Join this open forum on Tuesday, February 27 at 2 p.m. EST to hear our experts address you and your peers’ questions, concerns and outlooks on the current and coming states of the construction market.

RSMeans Data Online is North America’s premier construction estimating software. Available in three tiers designed to meet your construction estimating needs, RSMeans Data Online is proven to help building cost estimators develop accurate project budgets and validate costs.

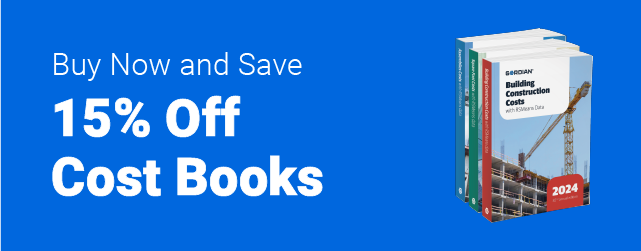

Line Item Search

Find items by keyword, MasterFormat number or browse the catalog by division to locate the material, task or construction cost you need.

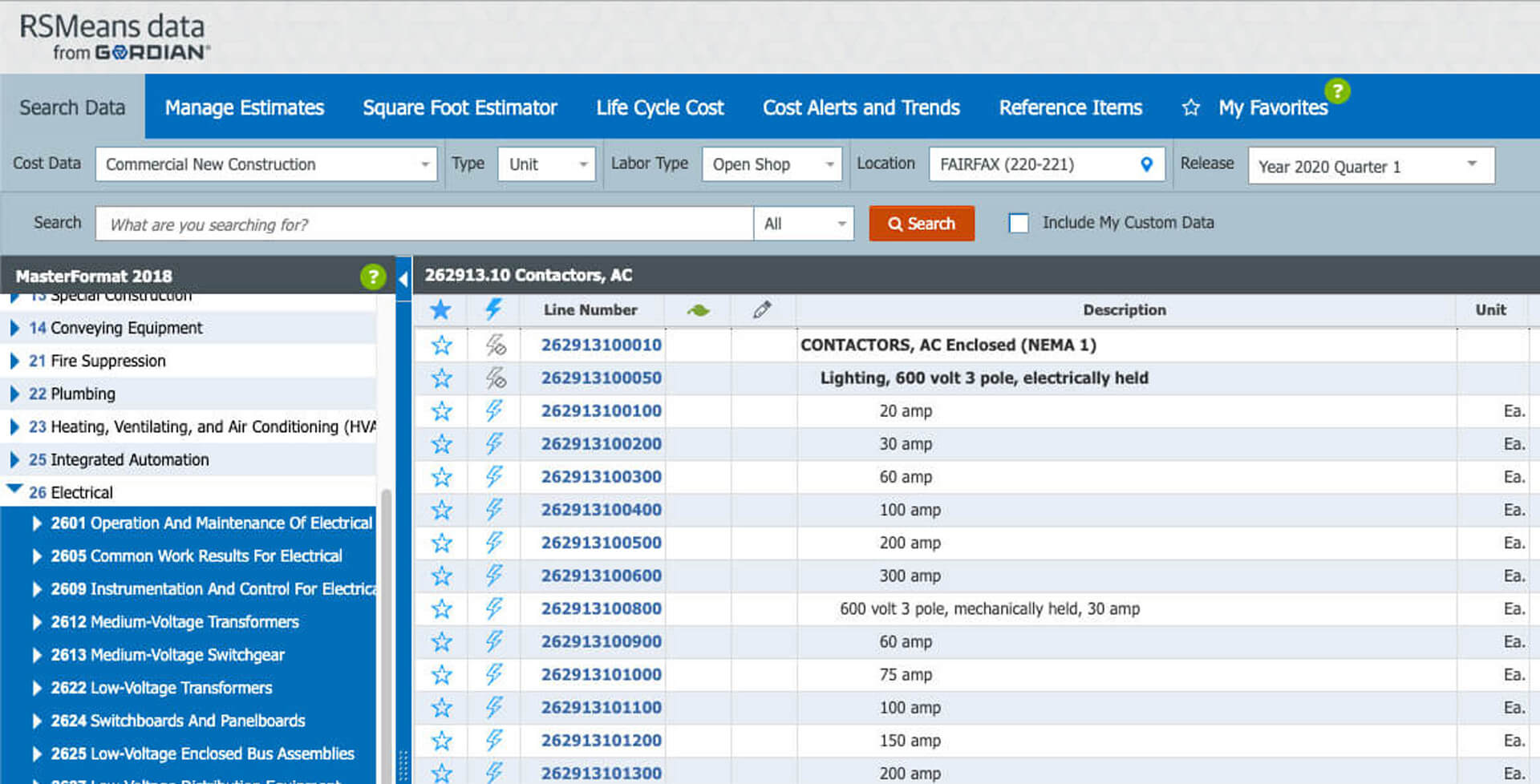

Advanced Reporting

Customize the look and feel of your estimate to include the right information in the right order.

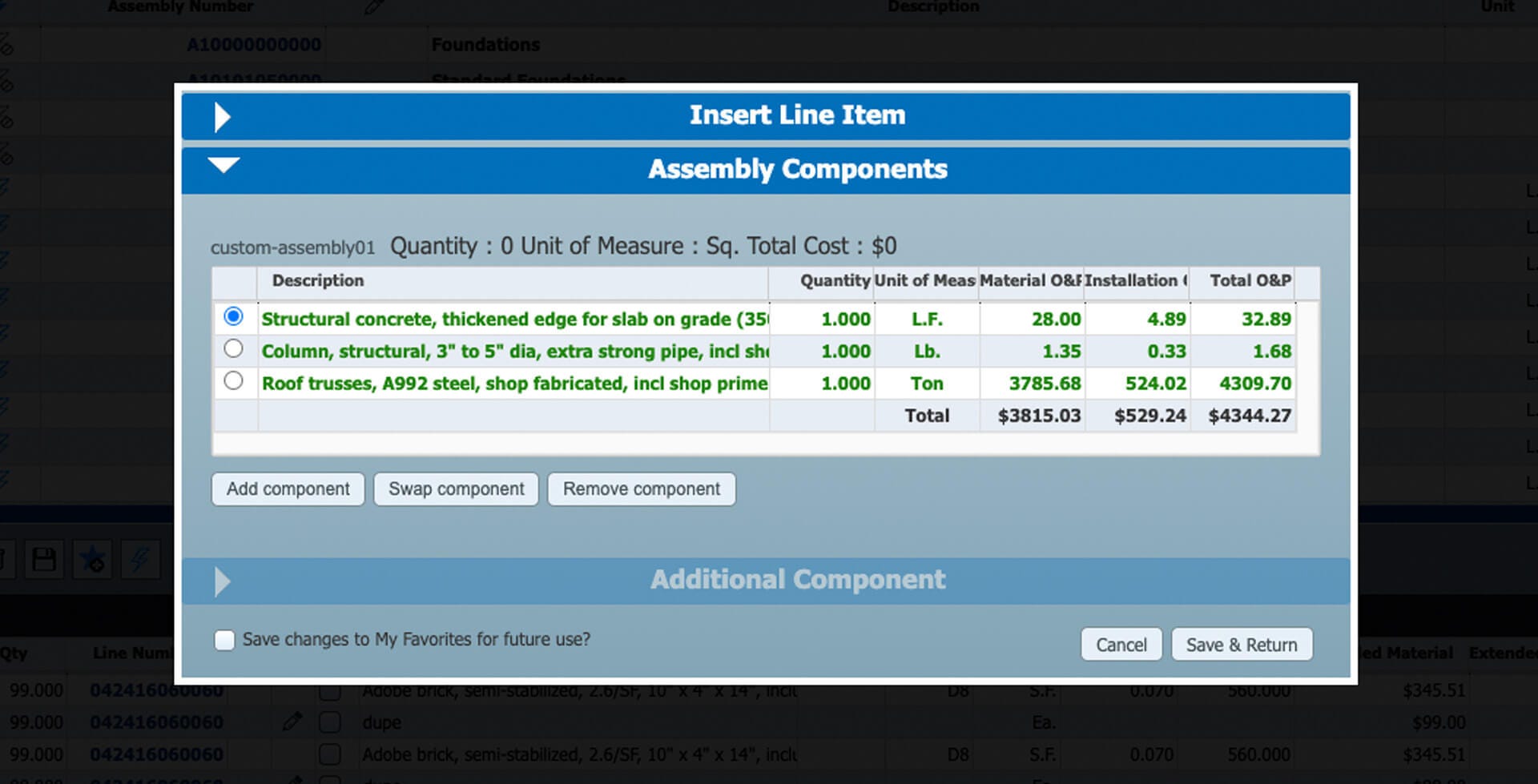

Custom Assemblies

Build your own assemblies for custom systems within your estimate and save them for later use.

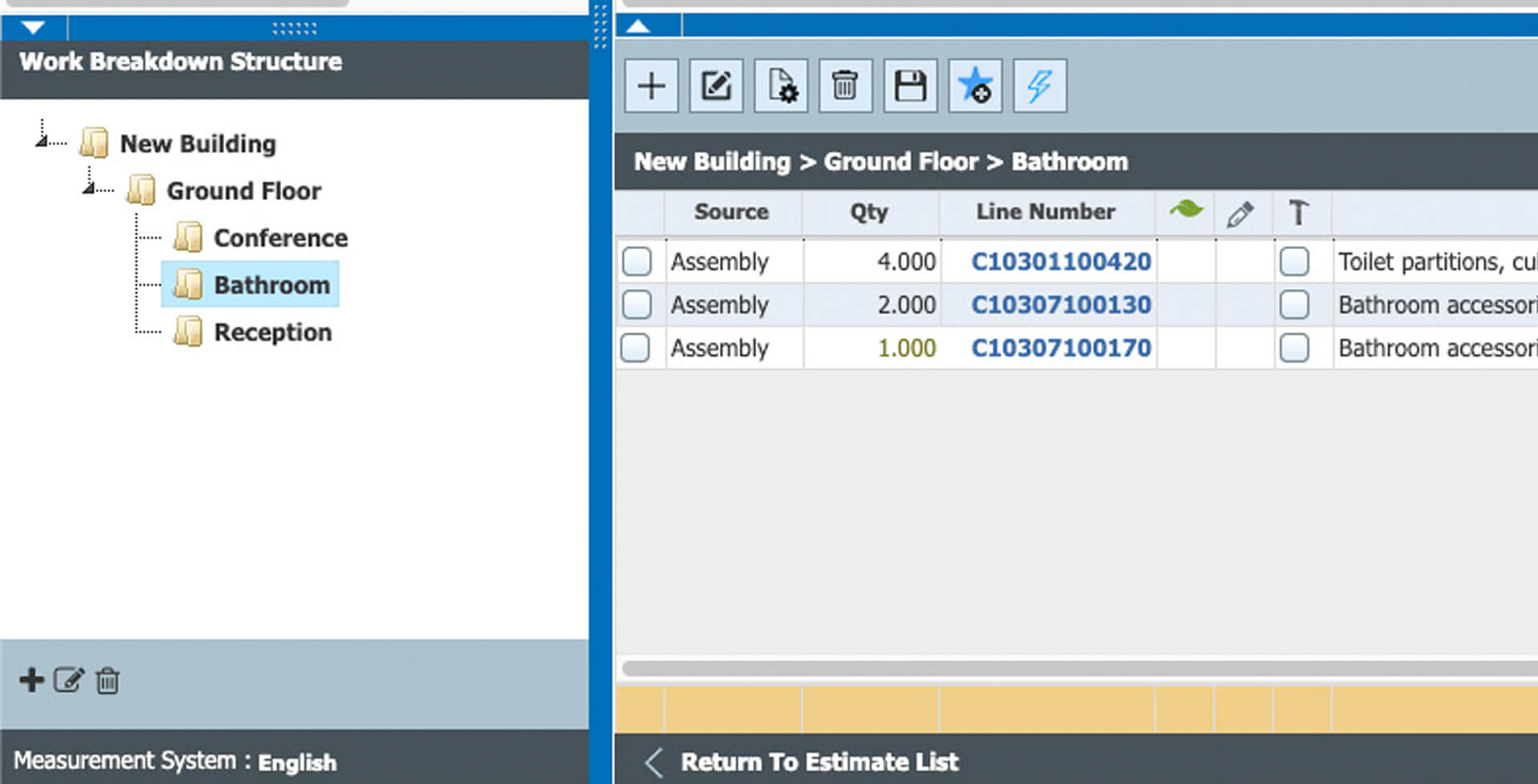

Work Breakdown Structures

Define the structure of your estimate and stay organized while building out rooms or floors. Organize by trade, by room or design your own system.

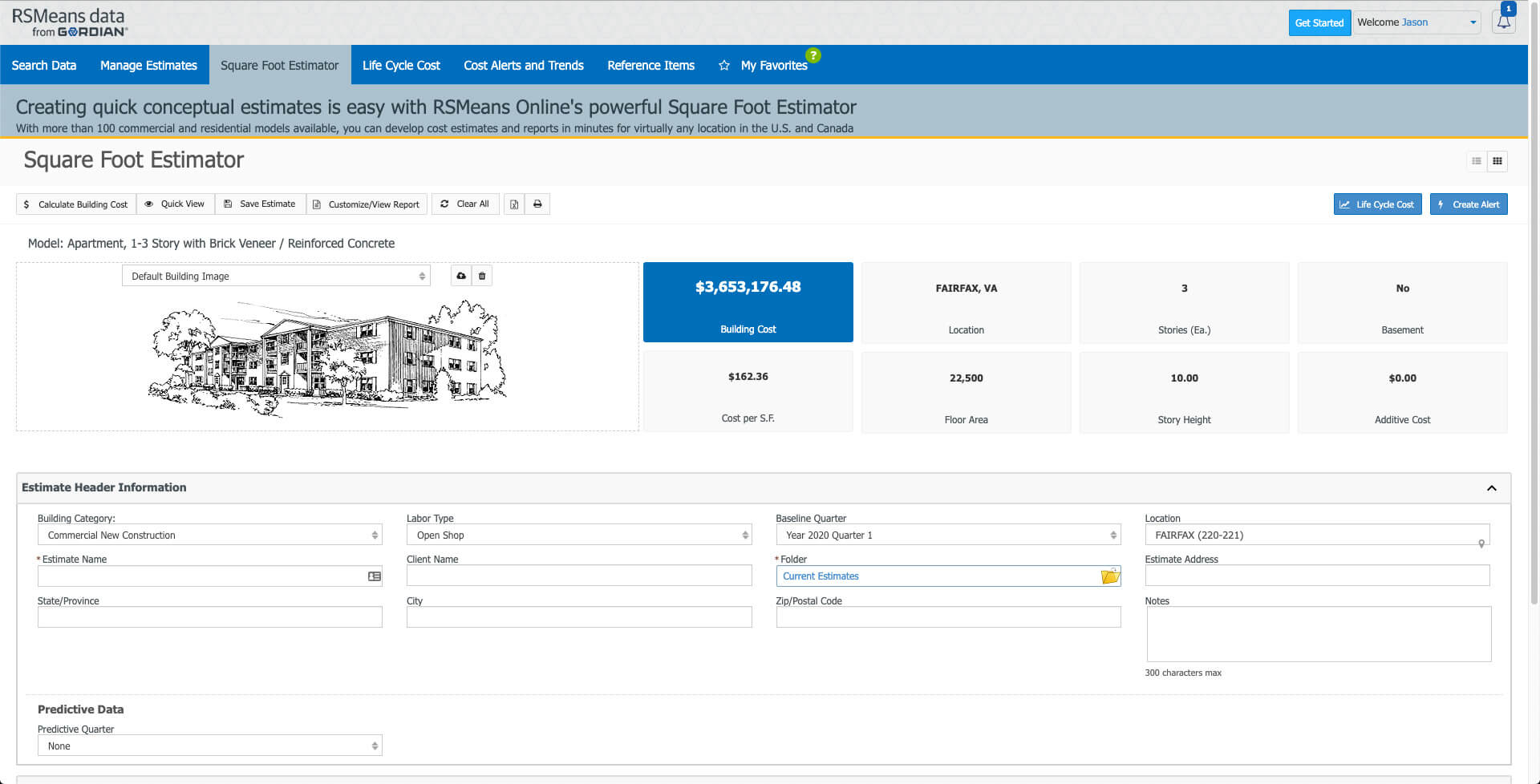

Square Foot Models

Create a conceptual estimate fast with an expansive library of existing models you can edit to generate costs for your project’s location.

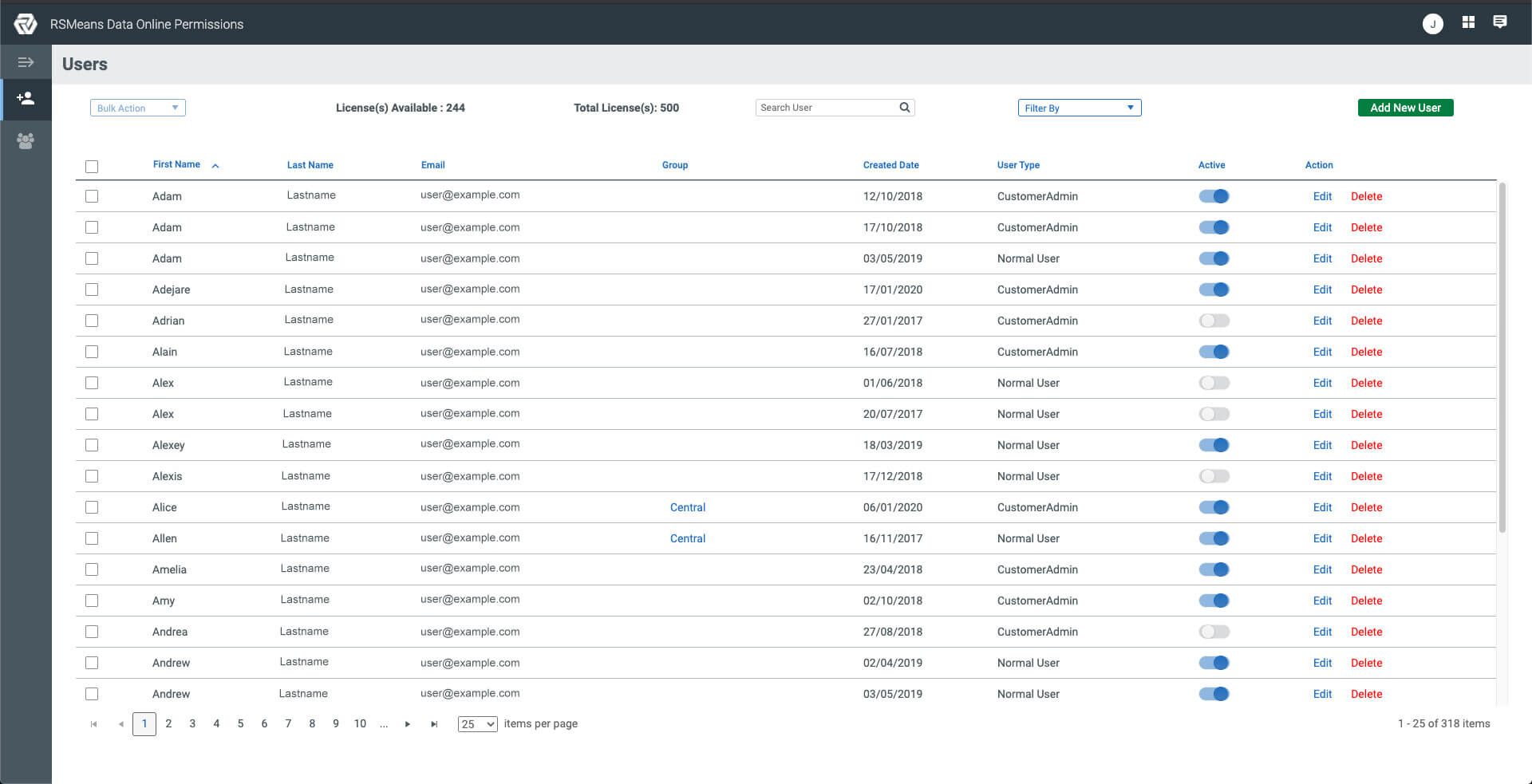

Permissions and Sharing

For collaboration in larger organizations, set controls around users and folders where estimates are stored.

North America’s most trusted construction costs

for more than 80 years.

North America’s most trusted construction costs

for more than 80 years.

Real Talk from RSMeans Data Users

Trusted by Architects, engineers, estimators, contractors and construction cost estimators.

RSMeans Data: Construction Costs You Can Rely On

RSMeans Data Online is your single source for immediate access to the industry’s most trusted source of up-to-date and reliable construction cost estimating data with advanced estimating tools.

Explore key capabilities at your own pace with these video demo playlists.

SEE HOW IT WORKSNewly added construction training courses and seminars.